Introduction to a Critical Tool

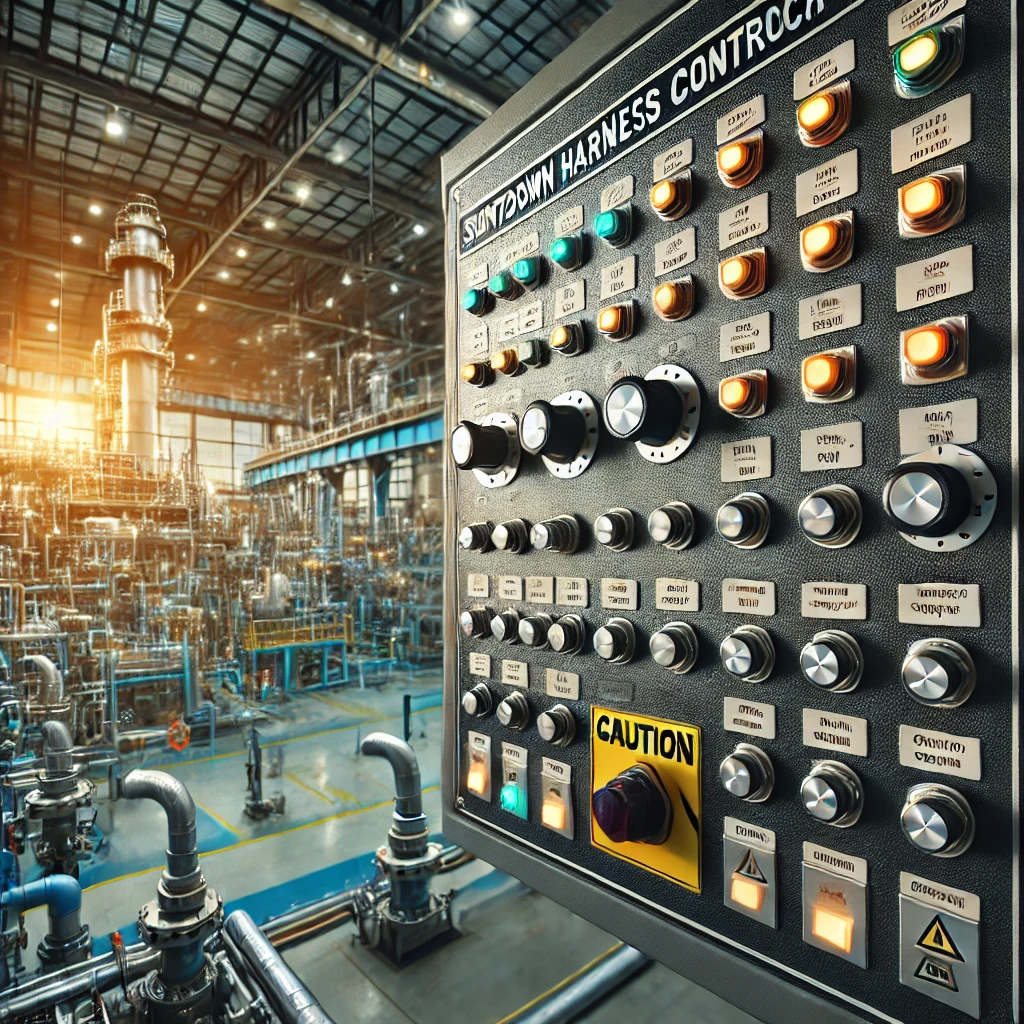

In the realm of industrial operations, certain components stand out for their critical roles in ensuring safety and efficiency. The ACTT Service Program SP 3-872-009 Shut Down Harness represents one such component. This article delves into the specifics of this harness, exploring its utility, functionality, and importance in various industrial applications.

Understanding the ACTT SP 3-872-009 Shut Down Harness

The actt service program sp 3-872-009 shut down harness is a specialized tool designed for emergency shutdown procedures in industrial settings. This device is crucial in scenarios where immediate cessation of operations is necessary to prevent accidents, protect equipment, or ensure compliance with safety regulations. Essentially, it serves as a fail-safe mechanism, integrating seamlessly into broader control systems to provide a quick response capability.

Core Components of the ACTT SP 3-872-009 Shut Down Harness

- Control Interface: The control interface is the user interaction gateway for the harness. It allows operators to program and manually trigger the shutdown process if needed. This interface is typically robust, designed to withstand industrial environments and provide clear, intuitive controls for users.

- Signal Receivers: Integral to the system, signal receivers are tasked with gathering data from various sensors located throughout the industrial setup. These receivers are highly sensitive and calibrated to detect abnormal signals that indicate potential hazards or malfunctions, thereby initiating the shutdown protocol.

- Relay Systems: The relay system acts as the executor within the harness. Once a shutdown signal is confirmed as necessary by the control unit, these relays actuate to disrupt power or operational flows, effectively bringing the machinery or process to a halt. These systems are designed for rapid response and reliability to ensure that when a shutdown is necessary, it is executed without fail.

- Power Supply Unit: Given the critical nature of the shutdown harness, it often includes a dedicated power supply unit that can maintain functionality even in the event of a main power failure. This unit ensures that the shutdown process is foolproof, capable of operating independently of the facility’s main power grid.

Design Features

Scalability: As industrial operations grow or change, the scalability of safety systems like the shutdown harness becomes crucial. The design allows for scalability in system complexity and size, accommodating increased inputs and sensors without significant alterations to the core syste

Modularity: The harness is designed to be modular, allowing for easy integration into a variety of industrial systems. This modularity also facilitates quick repairs and replacements of individual components without needing to overhaul the entire system.

Redundancy: To ensure reliability, the design often incorporates redundancy in critical components such as power supplies and relay systems. This redundancy guarantees that even in the event of a component failure, the harness can still perform its essential functions.

Environment Proofing: Industrial environments can be harsh, with exposure to extreme temperatures, vibrations, and corrosive substances. The design of the SP 3-872-009 includes protective measures such as robust casing, vibration dampeners, and corrosion-resistant materials to withstand these conditions.

Importance in Industrial Applications

The harness finds its importance in its ability to rapidly and effectively halt operations without human intervention. Industries such as chemical processing, oil and gas, and manufacturing, where the risks of continued operation during a fault are high, rely heavily on such systems to maintain safety standards and protect human lives and capital assets.

Why Implement the ACTT SP 3-872-009 Shut Down Harness in Industrial Settings?

In the complex and hazard-prone landscapes of industrial operations, the necessity for robust safety systems is paramount. The actt service program sp 3-872-009 shut down harness emerges as a critical component within these systems, offering an indispensable tool for ensuring operational safety and compliance. Here’s an in-depth exploration of why industries are increasingly turning to this specialized shutdown harness.

Enhanced Safety Compliance

One of the primary reasons for implementing the actt service program sp 3-872-009 shut down harness is its contribution to heightened safety standards. The harness is designed to meet, if not exceed, the rigorous safety regulations that govern high-risk industries like oil and gas extraction, chemical manufacturing, and power generation. By integrating such a system, facilities ensure they not only adhere to legal safety standards but often surpass them, thus safeguarding both personnel and the environment from potential hazards.

Immediate Risk Mitigation

The very nature of the shutdown harness is to act swiftly and decisively in the face of operational anomalies. Whether due to mechanical failure, process deviation, or external factors, the harness can detect issues and initiate a shutdown before these irregularities lead to accidents or disasters. This immediate response is crucial in environments where even a small delay can result in significant harm or operational loss.

Minimization of Operational Downtime

Unexpected downtime can be costly for any industry. The shutdown harness helps minimize these interruptions by addressing potential problems before they escalate into major faults that require extensive repairs or cause prolonged shutdowns. By preserving critical equipment from damage through timely deactivations, the harness ensures that systems can be brought back online as quickly and safely as possible.

Cost Efficiency

Investing in an ACTT SP 3-872-009 Shut Down Harness may seem like an additional expense, but the long-term savings are substantial. The cost of a shutdown system is negligible compared to the potential financial losses from equipment damage, legal liabilities, and reputational harm resulting from industrial accidents. Furthermore, insurance premiums may decrease as a result of implementing advanced safety technologies, adding another layer of cost benefit.

Future-Proofing Operations

As industries evolve and new technologies emerge, the adaptability and upgradeability of safety systems like the shutdown harness become vital. The ACTT SP 3-872-009 is designed with future enhancements in mind, allowing for integration with more advanced sensors and control systems as they become available. This makes it a forward-thinking choice that can adapt to future safety requirements and technological advancements.

Operational Mechanics: How It Works

The harness operates through a series of well-coordinated steps:

- Detection: Sensors detect anomalies and send a signal to the control unit.

- Decision: The control unit evaluates the signal to determine the appropriate response.

- Action: If a shutdown is warranted, the relay system activates, ceasing operations.

Installation and Maintenance: A Step-by-Step Guide

Installation:

- Integrate the harness into the existing control system.

- Connect all sensors and power supply units.

- Program the control interface according to operational parameters.

Maintenance:

- Regular testing to ensure responsiveness.

- Examination of most components for use and tear.

- Firmware updates to the control unit for enhanced functionality.

Common Issues and Solutions

Despite their powerful design, users may encounter dilemmas such as for example:

- Signal Interference: Ensuring that signal paths are clear and well-shielded can mitigate this.

- Component Failure: Regular maintenance and timely replacement of components prevent failures.

Main Applications and Future Prospects

The harness is primarily used in high-risk industries requiring stringent control measures. Looking ahead, the integration of smarter technologies and more responsive sensors is likely to enhance its effectiveness, making it an even more integral part of industrial safety systems.

Conclusion: Ensuring Industrial Safety and Efficiency

The actt service program sp 3-872-009 shut down harness is more than just a component; it’s a critical safety tool that underscores the importance of advanced planning and response strategies in modern industries. By understanding its functionality and maintaining its operation, industries can safeguard against unforeseen events, ensuring both safety and operational integrity.