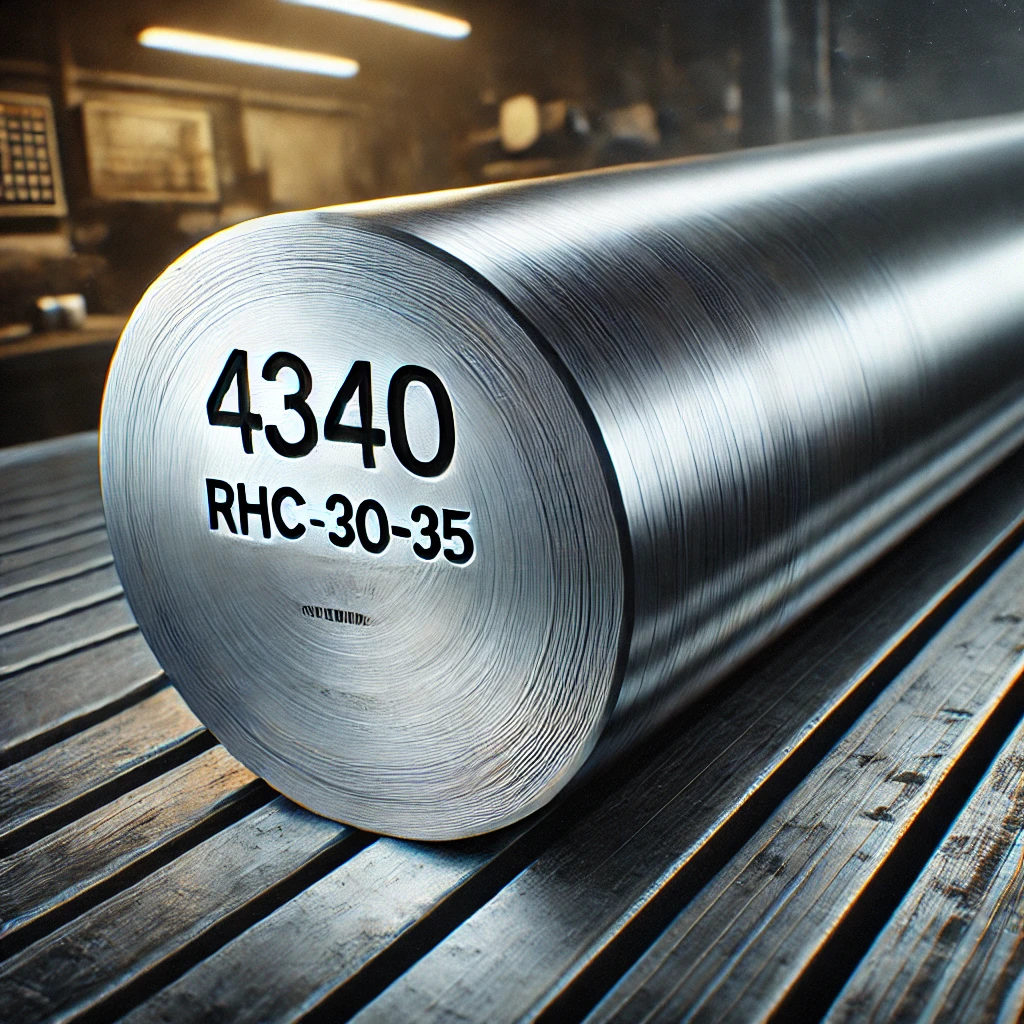

Introduction to 4340 RHC 30-35 Round Bar

In the realm of metallurgy, different steel grades serve distinct purposes across various industries. Among these, the 4340 RHC 30-35 Round Bar Supplier stands out due to its robust properties and versatility. This article delves deep into the world of 4340 steel, exploring its characteristics, applications, and the critical process of selecting a reliable supplier.

What Exactly is a 4340 RHC 30-35 Round Bar?

4340 metal is a high-strength, low-alloy metal which has chromium, dime, and molybdenum. Known for its toughness and strength, it is often referred to by its specific hardness range of Rockwell C 30-35. The “round bar” designation refers to the circular cross-sectional shape of the steel, which is commonly used in machining and tooling applications.

Popularity of 4340 RHC 30-35 Round Bar

The popularity of 4340 RHC 30-35 Round Bar Supplier can be attributed to their superior strength-to-weight ratio and toughness. These characteristics make it an ideal choice for highly stressed parts in the aerospace and defense industries, as well as automotive and manufacturing sectors.

Properties of 4340 Steel

4340 alloy steel is celebrated for its high impact strength and deep hardenability. It can maintain its strength even when exposed to high temperatures, which is crucial for applications requiring durability and reliability. Key properties include:

- High Tensile Strength: Allows it to withstand high stress without permanent deformation.

- Good Ductility: It remains malleable under tensile stress.

- High Toughness: Resists fracture even when subjected to sudden shocks or impacts.

Heat Treatment: Why It’s Important

Heat treatment processes such as annealing, normalizing, and tempering are crucial for enhancing the mechanical properties of 4340 steel. These treatments help in achieving the desired hardness and strength, while also improving toughness and ductility. This adaptability makes 4340 steel suitable for a variety of demanding engineering applications.

Applications of 4340 RHC 30-35 Round Bar Supplier

Due to its robustness, 4340 steel is extensively used in industries where strength and endurance are paramount. Common applications include:

- Aerospace Components: Landing gears, structural sections, and other critical parts.

- Automotive Parts: Crankshafts, axle shafts, and gears.

- Tooling and Machinery: Tool holders, drill collars, and machine parts.

How to Choose the Best 4340 RHC 30-35 Round Bar Supplier

Selecting a competent supplier is crucial. Key factors to consider include:

- Quality Certifications: Guarantee the company sticks to international requirements like ISO 9001.

- Supply Chain Reliability: Evaluate their delivery timelines and supply chain robustness.

- Technical Support: Good suppliers provide customer service and technical assistance.

Main Benefits of Using 4340 RHC 30-35 Round Bar

- Durability: Exceptional strength increases the lifespan of components.

- Cost-Effectiveness: Reduces the need for frequent replacements.

- Versatility: Can be used across various sectors, enhancing its utility.

Common Sizes and Availability

4340 round bars are available in various diameters and lengths, which can be customized according to specific needs. Suppliers often stock a range of standard sizes, facilitating quick delivery and availability.

Why Choosing the Right Supplier Matters

The right supplier ensures high-quality material that meets industry specifications and can significantly affect the performance and reliability of the final product. Trustworthy suppliers provide material traceability, consistent quality, and competitive pricing.

Conclusion: The Significance of 4340 RHC 30-35 Round Bar in Modern Industries

The 4340 RHC 30-35 round bar is a cornerstone in the fabrication of high-strength, durable components across various high-stress industries. Understanding its properties, applications, and the importance of selecting a reliable supplier can empower businesses to make informed purchasing decisions, ensuring operational efficiency and product excellence. Whether you are in aerospace, automotive, or manufacturing, integrating 4340 round bars into your projects can lead to superior outcomes and enhanced performance.

FAQs About 4340 RHC 30-35 Round Bar Suppliers

1. What is a 4340 RHC 30-35 round bar?

A 4340 RHC 30-35 round bar is a high-strength, low-alloy steel bar characterized by a hardness range of Rockwell C 30-35, ideal for components requiring high stress resistance.

2. What industries commonly use 4340 steel round bars?

4340 steel is widely used in aerospace, automotive, and heavy machinery industries due to its high strength, toughness, and resistance to wear and fatigue.

3. What are the key properties of 4340 RHC 30-35 steel?

Key properties include high tensile strength, good ductility, and excellent toughness, which make it suitable for high-stress applications.

4. Why is heat treatment important for 4340 steel?

Heat treatment processes like annealing and tempering enhance the mechanical properties of 4340 steel, such as hardness, strength, and ductility, making it more suitable for various industrial applications.

5. How do I choose the best supplier for 4340 round bars?

Look for suppliers with quality certifications, reliable supply chains, and robust customer support. Ensure they can provide product traceability and meet specific industry standards.

6. What sizes do 4340 RHC 30-35 round bars come in?

These round bars are available in various diameters and lengths, often customizable to meet specific requirements. Suppliers typically offer a range of standard sizes for immediate delivery.